A team of researchers, led by Cornell University, has found a way to make metals and alloys much stronger when they face extreme impacts. By adding...

Vous n'êtes pas connecté

- English

- Français

- عربي

- Español

- Deutsch

- Português

- русский язык

- Català

- Italiano

- Nederlands, Vlaams

- Norsk

- فارسی

- বাংলা

- اردو

- Azərbaycan dili

- Bahasa Indonesia

- Հայերեն

- Ελληνικά

- Bosanski jezik

- українська мова

- Íslenska

- Türkmen, Түркмен

- Türkçe

- Shqip

- Eesti keel

- magyar

- Қазақ тілі

- Kalaallisut ; kalaallit oqaasii

- Lietuvių kalba

- Latviešu valoda

- македонски јазик

- Монгол

- Bahasa Melayu ; بهاس ملايو

- ဗမာစာ

- Slovenščina

- тоҷикӣ ; toğikī ; تاجیکی

- ไทย

- O'zbek ; Ўзбек ; أۇزبېك

- Tiếng Việt

- ភាសាខ្មែរ

- རྫོང་ཁ

- Soomaaliga ; af Soomaali

Rubriques :

Maroc - TECHXPLORE.COM - Engineering - 05/Mar 16:42

Maroc - TECHXPLORE.COM - Engineering - 05/Mar 16:42

Nanoscale tweaks help alloy withstand high-speed impacts

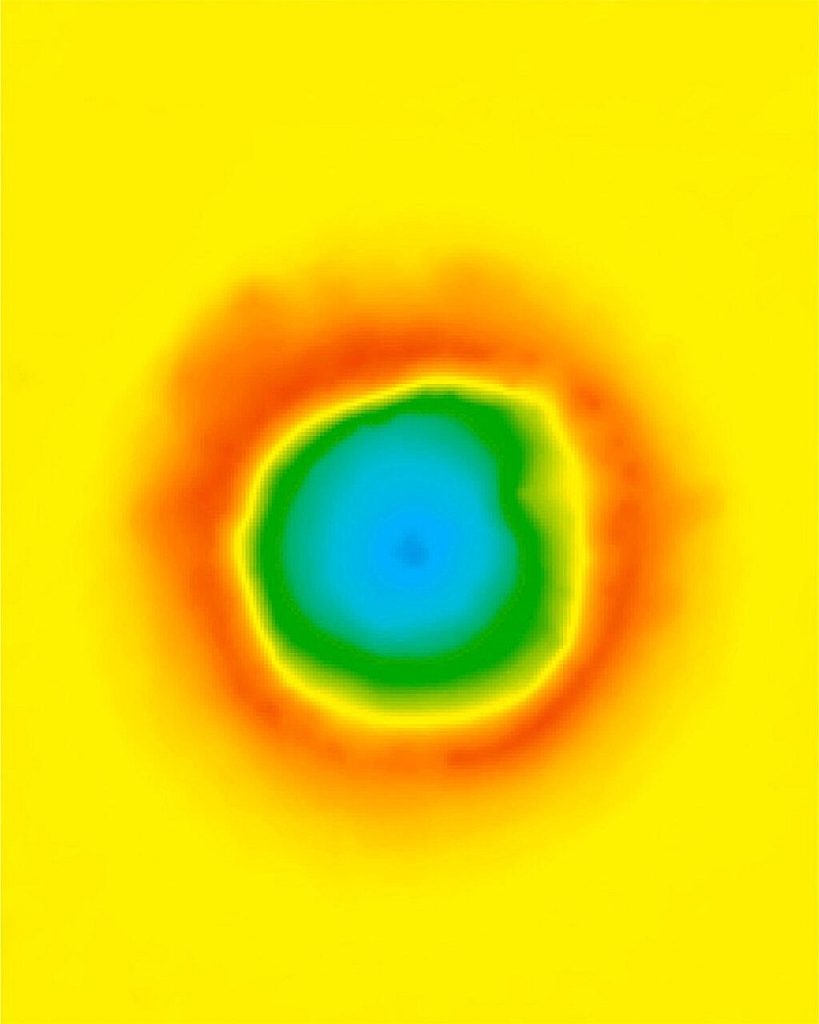

A Cornell-led collaboration devised a new method for designing metals and alloys that can withstand extreme impacts: introducing nanometer-scale speed bumps that suppress a fundamental transition that controls how metallic materials deform.

Articles similaires

AI reveals new way to strengthen titanium alloys and speed up manufacturing

Producing high-performance titanium alloy parts—whether for spacecraft, submarines or medical devices—has long been a slow, resource-intensive...

Introducing SAMA7D65 MPUs Available in System-in-Package and System-on-Chip with Advanced Graphics and Connectivity Features

Embedded developers must address the challenge of designing systems that achieve a balance between compactness,…

UNSW develops PV panel recycling method that recovers cell metals for upcycling

UNSW researchers were able to recover silicon from end-of-life solar PV panels pure enough for re-use in silicon carbide-based devices. Their novel...

Superelastic alloy that functions in extreme temperatures could aid space exploration

Researchers at Tohoku University have developed a titanium-aluminum (Ti-Al)-based superelastic alloy. This new material is not only lightweight but...

Ambercycle And Huilong Announce Partnership To Scale Circular Textile Materials

LOS ANGELES — February 26, 2025 — Ambercycle, a cutting-edge innovator in textile recycling, has entered into a partnership with Zhejiang Huilong...

Faded markings on speed bumps in Bandar Kinrara raise safety concerns

RESIDENTS of Bandar Kinrara in Puchong, Selangor are calling for improved visibility of speed bumps in their neighbourhood to prevent accidents and...

Hexcel And FIDAMC Join Forces To Shape The Future Of Composite Materials

STAMFORD, Conn. — March 5, 2025 — The Foundation for Research, Development and Application of Composite Materials (FIDAMC) a research and...

Les derniers communiqués

-

Adobe Brings Conversational AI to Trillions of PDFs with the New AI Assistant in Reader and Acrobat

Adobe - 21/02/2024

-

Laura Frigenti takes the Helm as Chief Executive Officer of the Global Partnership for Education

Global Partnership for Education - 05/12/2022